Contents

[ hide ]

- 1 Profile of CONTIGO’s partner Seet Kamal

- 1.1 Supply chain

- 1.2 Products

- 1.3 Location

- 1.4 Founded in 1997

- 1.5 History

- 1.6 Cooperation with CONTIGO since 2006

- 1.7 Structure of the business

- 1.8 Sales

- 1.9 Goals

- 1.10 Special features

- 2 Fairtrade classification

- 3 Fairtrade aspects

- 3.1 No child labour

- 3.2 No discrimination

- 3.3 Fair wages

- 3.4 Humane working conditions

- 3.5 Transparency

- 4 Monitoring

- 5 Country information

- 6 Photos

- 7 Video

Profile of CONTIGO’s partner Seet Kamal

Supply chain

Trading Partner: Seet Kamal, major company

Function: Producer

Structure: Own production plant, affiliated production groups

Tradeway: Direct import CONTIGO

Products

- Note- and pocketbooks with handmade recycling paper and leather covers

- Stationary items

- Lamp shades and seasonal decoration made from various papers

Location

Jaipur, in the state of Rajasthan, India – distance to Europe: 6,100km

Founded in 1997

History

- 1997: Establishment of the company by Gautam Nathany with 5 employees and a group of artisans. The company´s name traces back to his grandparents first names. Focus on paper products and notebooks

- 2004: Export trainings by CBI Holland facilitated the access to international trade fairs

- 2006: CONTIGO meets Seet Kamal for the first time, cooperation starts

- Till 2011: Diversification of product ranges, office products and home decoration, number of staff increases to 30

- 2011: Seet Kamal is awarded with the „Green Award“ (see below)

- 2014: Construction of a new five floor production site, 350 employees and crafters

- 2016: Purchase of neighbouring land to build a modern warehouse for materials. Intensive internal reorganisation of all production steps and processes in order to improve quality and competitiveness

- 2017: Construction of another building as packaging and shipping center, number of employees and crafters raises to 500

Cooperation with CONTIGO since 2006

Structure of the business

Number of employees:

Ca. 500 employees, working in

- management, administration, accounting (20)

- HR department, internal safety (4)

- marketing, sales department (6)

- design, graphic and product development (10)

- planning of production, quality control (12 with assigned teams)

- packaging, labelling (16 with assigned teams)

- production: specialists in screen printing and laser techniques, screen making (4)

- production and quality control (ca. 420 artisans in teams of 7-12 persons under the guidance of a supervisor, proportion of women: 40%)

Work environment:

Description of production site:

- Entrance area with gate keeper’s house, room for child care, consulting room for health agent, canteen

- Two multi-floor buildings for administration and production

- Adjoining building for storing different materials and chemicals

- Rear buildung for notebook production

- Neighbouring plant: warehousing cardboard boxes, packaging and despatch department

- Located outside (still under construction): production facility for packaging and gift boxes

Organisation of workforce:

A) Production steps at the main production site (examples):

- Production of notebooks with leather covers:

- Cutting and embossing the leather

- Dyeing with sponges or spraying pistols

- Cutting and binding of the paper booklets (recycling paper)

- Assembling, glueing and sewing of the different parts

- Quality check during and after the production

- Production of honeycomg paper decoration and lamp shades

- Cutting and punching of paper in various shapes

- Embossing of the fold line, folding, assembling, glueing

- Affixing the magnetic clasps

- Quality check during and after the production

- Department for printing and laser cutting of single paper sheets

- Screen printing, lamination, texture printing, digital laser design with modern machines

- Traditional screen printing, own screen maker at the company

- Production of paper garlands:

- Punching of the papers

- Sewing of the garlands and mobiles with electric sewing machines

- Quality check during and after the production

B) Production steps outside the main production site

- Production of handmade paper sheets (made of recycling cotton)

- Digital printing

- Dyeing of textiles for various home decor and fashion accessories

Sales

- Home market (10%)

- Exports (90%) to Germany, Italy, UK, Spain, U.S.A., and Australia

Goals

- To set up new business areas (packaging concepts and packaging design)

- To modernise the company, including warehouse, distribution, administration

- To optimise all production steps

- To implement complete quality control and permanent innovation of the product ranges

- To establish environment friendly production

Special features

- Environmental commitment:

- Seet Kamal runs an own water treatment plant for waste water on the roof top. Waste water from screen cleaning returns to the water cycle, water consumption decreased by 70%.

- Green area: all new buildings have small balconies with hanging gardens, courtyard with tree population, own plant nursery, bird bath places

- Social commitment:

- Support of a school for mentally disabled children in Jaipur

- Internal: Seet Kamal offers health checks (also for the employee´s families, see below)

- Awards:

- 2011/2012: Green award (for a very environmentally friendly production), awarded by FORHEX (Handicraft Exporters Association of Rajasthan)

- 2015: „Best exporter in paper category“, awarded by the Export Promotion Council of India (EPCH)

Why does CONTIGO work with Seet Kamal: CONTIGO values the innovative power of the company. All processes, product ranges and quality are permanentally improved. The working conditions are best practise. A long-standing partnership with mutual trust and a personal relationship has been developed.

Fairtrade classification

FTA = Fairtrade Approved

Fairtrade aspects

Seet Kamal complies with the following Fairtrade Principles:

No child labour

No discrimination

No discrimination due to gender, disability, religion, ethnicity, sexual orientation, political orientation, or infection with HIV

Fair wages

- Minimum wages in the state of Rajasthan: (INR = Indian Rupee)

- un-skilled workers: INR 5,382 / month

- semi-skilled workers: INR 5,642 / month

- skilled workers: INR 5,902 / month

- Average salaries at Seet Kamal (production and quality control):

- un-skilled workers: INR 5,400 / month

- semi-skilled and skilled workers: INR 6,400 / month

- Seet Kamal established bank accounts for all employees and crafters

- Payment is transferred to bank accounts or paid out as cheque

- Salary is increased due to inflation once a year (October / November)

- Bonus payment due to performances

- Higher surcharges for Sundays and bank holidays

- Continuation of payments in case of less work

Humane working conditions

Working hours:

- 8 hours/day

- 3 breaks (30 minutes lunch break, two tea breaks 15 minutes each)

- 6 days/week

Social benefits:

For employees at Seet Kamal and all artisans in production groups:

- Paid leave (9 festival holidays, 21 days for recreation)

- Paid sick leave and after accidents

- Contributions to health insurance ESI (=Employee State Insurance), employer pays 4,75% and employee 1,75% of monthly gross wage

- Contributions to pension scheme PF (=Employees´ Provident Fund), employer and employee pay each 12% of monthly gross wage

- Voluntary service: Seet Kamal pays accident insurance for everybody

- Voluntary service: financial support when employee buys a high quality helmet for the moped (as there are many accidents and injuries)

- Special health agent in the Human Ressorces Department, who is in charge of health services for all staff members and their families, doctors and hospital consultation, helps with formalities, claims for the insurer

- Women commitee (6 members) who takes care of gender issues and the interests of female employees

- Seet Kamal established a medical camp for regular health check ups for all staff members, focus on diabetes and high blood pressure, free medication for diseased employees

Educational opportunities:

- First aid course

- Fire safety exercises and other emergency exercises

Occupational safety:

- All safety standards are met in the various departments. Information boards in all departments help to raise awareness

- Protective clothing is provided (gloves, breathing masks)

- Escape and rescue plans are installed

- Fire protection is installed, fire protection manager is in charge of maintenance of all fire extinguishers, external checks are executed

- Janitor takes care of repairs, maintenances and safety of all machines, checks safety of the drinking water

- First aid kits are easily accessible to everyone, 10 trained first aider

- Separated and locked warehouse for chemicals (colours and glue) and other flammable substances

Transparency

- Work contracts are available

- Payroll is available

- Pay slips are available

- SAR (Self Assessment Report) was duly submitted to CONTIGO

Monitoring

- Personal visits in Jaipur (2008, 2011, 2014, 2017, 2020)

- Feedback interview during several visits in Germany

- Machine-made paper sheets are certified by FSC (=Forest Stewardship Council, products from responsible forest management)

- Company audit by AQSR (American Quality Standards Registrars), ISO 9001-2008, safety, quality and efficiency

- Company audit by ICS (Initiative clause sociale, French company), focus on social, health and safety standards

Country information

See Encyclopaedia Britannica: India

Photos

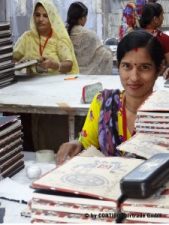

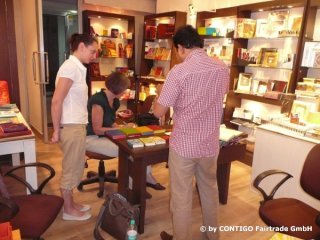

Visiting Seet Kamal in Jaipur (2017):

Seet Kamal receives award:

Visiting Seet Kamal in Jaipur (2014):