Contents

[ hide ]

- 1 Profile of CONTIGO´s partner Afrikiko

- 1.1 Supply chain

- 1.2 Products

- 1.3 Location

- 1.4 Founded in 1996

- 1.5 History

- 1.6 Cooperation with CONTIGO since 1996

- 1.7 Structure of the business

- 1.8 Sales

- 1.9 Goals

- 1.10 Special features

- 2 Fairtrade classification

- 3 Fairtrade Aspects

- 3.1 No child labour

- 3.2 No discrimination

- 3.3 Fair wages

- 3.4 Humane working conditions

- 3.5 Transparency

- 4 Monitoring

- 5 Country information

- 6 Photos

Profile of CONTIGO´s partner Afrikiko

Supply chain

- Trading Partner: Afrikiko, microenterprise

- Function: Producer

- Structure: own production facility, affiliated production groups

- Tradeway: Direct import CONTIGO

Products

Decoration Accessories made of soapstone

Location

Tabaka (30 km southwest from Kisii-City, in Kisii County), Kenya – distance to Europe: 6,000 km

Founded in 1996

History

- 1994/1995: Employee of GTZ (now GIZ – German Society for International Cooperation) discover potential of Kenyan soapstone figurines for the international market; they ask Muriuki Njeru (a computer scientist) to introduce them on the German market

- 1995: Foundation of Afrikiko by Muriuki Njeru, headquarter in Berlin, first trade fair exhibitions

- 1995: CONTIGO meets Afrikiko and is the first customer of the new company

- 1996: Six families are employed in the production of soapstone figures in Tabaka, Kisii County (22 people in total)

- 1996-1997: Muriuki starts structuring work in Tabaka and hires a production manager and three designers (Daniel, Shem, and Moses)

- 1995-2003: Slow business development

- 2002: Muriuki´s wife Dagmar decides to no longer continue work as a social worker, and takes over the sales department at Afrikiko

- Since 2003: Main focus on innovative designs, improved product quality, new colours and shapes. Dagmar invents the heart shape which becomes an international success

- Since 2004: New customers can be acquired, large orders arrive

- 2005/2006: Due to strong demand from international businesses, the soapstone handicraft booms. Strong competition starts as other businesses in Tabaka copy the designs from Afrikiko

- 2006-2007: Muriuki moves to Kenya, further re-organisation of the business, a new designer is hired

- 2nd half of 2007: Grave political unrest in Kenya, especially in the region around Kisii, losses in production -> economic burglary

- From mid of 2008 on: Stabilisation of political environment, Greta Herbst (CONTIGO’s designer) visits Afrikiko in Tabaka and works with Afrikiko’s designers for a month to develop new products

- 2009: Afrikiko’s business is improving again: large orders from international companies arrive, Afrikiko changes the name of the production site in Kenya into Tarazu

- 2009: Tarazu becomes member of KEFAT (= Kenyan Federation for Alternative Trade)

- 2010: District office in Nairobi is closed down. All departments such as administration, production and shipping, are now centralised in Tabaka

- Since 2010: Stronger inclusion of women in the traditionally male-dominated sphere (colouring, engraving and shaping the soapstone)

- 2014: Workshops of carvers move to the different soapstone sources, establishment of central shelters for the different production steps, improvement of quality control

- 2017: All in all 26 employees work in Tabaka and Nairobi permanently

- 2020: Situation under Covid pandemic

- March: difficult order situation, large export orders are canceled or withheld, outstanding payments not made. All 46 employees are kept on without loss of pay

- May to July: Afrikiko is the only company in Tabaka still offering employment, work is performed under strict security measures. Introduction of 5-day instead of 6-day week due to reduced orders

- October: slow come back of export customers, yet overall a high drop in sales is evident compared to the previous year

- 2021: Due to the Covid pandemic a number of female staff members left Afrikiko because they are responsible for childcare during the lockdown; others moved from Tabaka to be near their relatives or they took the opportunity to change their jobs

Cooperation with CONTIGO since 1996

Why does CONTIGO work with Afrikiko:

Our longest trading partnership in our company’s history is the one with Afrikiko. For both sides, it was the very first experience with a container order. Today, Afrikiko is the most important employer for the soapstone craftsmen in Tabaka. Over the years, a very intense personal relationship has been developed in addition to the business relationship. CONTIGO has been able to contribute to product development, help out in case of cash bottlenecks and place at least one volumeorder every year. What we appreciate about Afrikiko is the socially responsible way of working in Tabaka, the constant willingness to optimise work processes, the focus on quality and innovation. The readiness for high transparency in all areas of the company.

Structure of the business

- Permanent staff: 14 employees in Tabaka, 1 in Nairobi

- CEO: Murijuki Njeru

- Central departments: management, quality control, production management, product development, warehousing, export & shipping, supervision

- Condition of employment: A-levels or bachelor

- Staff receive fixed salaries

- Cooperation all year round with up to 500 artisans in Tabaka, divided into:

- 120-150 carver (thereof 1 woman)

- 140 artisans: soapstone is washed and sandpapered (3 men, 137 women)

- 80 dyer (32 men, 48 women)

- 60 designer (56 men, 4 women)

- Artisans receive piece rate payment

- Cooperation with 8 external, independant workshops

- Soapstone products (4)

- Wood products (4)

- Selected products only, quality control at Afrikiko in Tabaka

- Artisans receive piece rate payment

Organisation of work:

- Before starting with an order, all teams are intensively educated

- Afrikiko provides raw materials and other working tools

- Daily contact to supervisors of the different groups

- Finished carvings are delivered by the representatives of the handicraft groups (8 groups) for quality control. Acceptance or refinishing, if necessary

- Regularly agreements between the different supervisores with regards to current orders

Work environment:

- Main building includes different offices for management, product development, warehousing, teaching new artisans etc.

- Open workshops (shelters) near to the main building for all production steps after first carving (raw shapes): fine carving, washing, sandpapering, dyeing and engraving

- Predominantly team work, specialisation on one production steps. Teams are formed on their own, have a group leader

- Every group is controlled by a supervisor (who examines every single product before it goes next)

- Payment in groups: piece rate payment (see below: Fair wages)

Production process:

- First carve near stone deposits in the surroundings of Tabaka (predominantly done by men, physically strenuous, higher payment)

- Control and transport to Afrikiko

- Second carve (fine)

- Washing and sandpapering (repeated many times), must be performed very carefully for the further step (colour application)

- Sun drying

- Colouring with textile colours

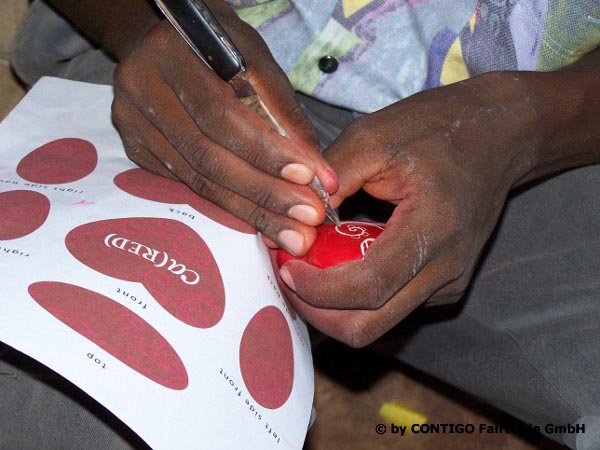

- Designing the finished products: engraving patterns, words, motives

- Wax polishing

Artisans are allowed to choose if they would like to work in the central teams or if they want to work from home. Mothers with little children prefer to work from home.

Sales

- Exports (100%) to Germany, the U.S., Italy, UK, Greece, Colombia, Finland, Norway, Australia, Switzerland, and New Zealand

Goals

- To establish a social centre with the following activities:

- Child care for the afternoons

- Space for children to do homework

- Workshops for computer use

- Library for children

- To build further shelters for production that provide workers protection from sun and rain

Special features

- Afrikiko sets value on the private care and social work in the families, Afrikiko takes over the complete health insurance contributions for the permanent staff, free ambulant treatment at local hospitals for artisans (Afrikiko encourages all artisans to take this opportunity)

- Afrikiko can offer work all year round for their artisans

- Piece rate is above average compared to what is paid at other soapstone manufacturers

- Afrikiko strengthens women through offering jobs in special areas of responsibility (quality control), granting management positions and training in areas of work previously dominated by men (engraving)

Fairtrade classification

FTA = Fairtrade Approved

Fairtrade Aspects

Afrikiko complies with the following Fairtrade Principles:

No child labour

No discrimination

No discrimination due to gender, disability, religion, ethnicity, sexual orientation, political orientation, or infection with HIV.

Many different ethnicities (Luo, Kisii, Kikuju) work together at Afrikiko

Fair wages

- Payment system at Afrikiko

- Permanent employees receive a fixed monthly salary

- Most of the employees earn between KSH 40,000 – 45,000 /month (depending on responsibility)

- Permanent employees receive a fixed monthly salary

-

- Artisans receive piece rate

- This piece rate depends on expenditure of time and level of difficulty, is agreed before

- Bonus payment at the end of the month (in case of good work performance): 9% of order volume is paid out to the team as bonus

- Artisans receive piece rate

- Monthly salary is transferred to employees own bank account, all permanent staff and artisans have their own bank acounts

- At the end of each fiscal year, all employees (permanent staff, artisans, trucker) receive a bonus (depends on turnover)

- Permanent employees receive:

- Overtime pay (salary is increased by 30% when overtime is required)

- Holiday bonus (one month salary)

Humane working conditions

Working hours:

- 8 hours/day

- 2 breaks (breakfast and lunch)

- 6 days/week

Social benefits:

Permanent staff (14) receive:

- Payment of contributions to health insurance NHIF (employers and employees each pay half; in Corona Pandemic 2021 contributions are subsidised by the government)

- Payment of contributions to pension scheme NSSF (employers and employees each pay half; in Corona Pandemic 2021 contributions are subsidised by the government)

- Continued payment of wage in case of sickness or accident

- Paid holidays (26 days)

- In event of removal to Tabaka, Afrikiko pays the moving expenses for the employee

- Accommodation is provided by Afrikiko (at the moment for 5 females employees living outside of Tabaka)

Permanent staff and artisans receive:

- Financial support (interest-free loans)

- for school fees for employee´s children

- in case of emergencies, special family occasions (funeral, long illnesses, operations)

- Team building event: annual company celebration for all employees at Afrikiko. In addition Afrikiko has an own soccer team.

Educational opportunities:

- First Aid courses

- Double-loop learning at all production steps

- Afrikiko provides thorough training of new employees before working on orders

Occupational safety:

- Working gear and protective clothing (e.g. gloves, breathing masks) are provided by Afrikiko

Transparency

- Work contracts are available

- Payroll is available

- Pay slips are available

- SAR (Self Assessment Report) was duly submitted to CONTIGO

Monitoring

- Personal visits in Tabaka (2008, 2017)

- Feedback interview during several visits in Germany

- Member of:

- Kenyan Federation for Alternative Trade (KEFAT)

Country information

See Encyclopaedia Britannica: Kenya

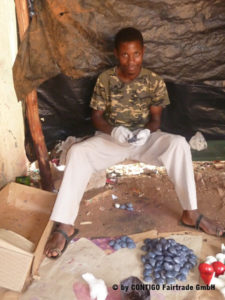

Photos

Pictures from March 2017

Pictures from 2008